Trailer Hitch Installation Las Vegas: Navigating the world of towing in the vibrant city of Las Vegas requires a reliable and expertly installed trailer hitch. This guide explores the diverse options available, from finding reputable installers to understanding the various hitch types and installation processes. We’ll delve into cost considerations, safety precautions, and maintenance tips to ensure a smooth and safe towing experience.

Whether you’re a seasoned tow enthusiast or a first-time hauler, understanding the nuances of trailer hitch installation is crucial. This comprehensive guide will equip you with the knowledge needed to make informed decisions, whether you choose professional installation or a DIY approach. We will cover everything from selecting the right hitch for your vehicle to understanding local regulations and ensuring your setup is both safe and legal.

Finding Trailer Hitch Installers in Las Vegas

Finding a reliable trailer hitch installer in Las Vegas is crucial for ensuring the safe and secure towing of your trailer. Numerous businesses offer this service, but choosing the right one requires careful consideration of factors like experience, pricing, and customer service. This section provides information to assist you in making an informed decision.

Reputable Trailer Hitch Installation Businesses in Las Vegas

Selecting a reputable installer is paramount for a successful and safe hitch installation. The following table lists several businesses known for their services in Las Vegas. Please note that this information is for general guidance only and should be verified independently. Addresses and phone numbers are subject to change, and website availability is not guaranteed.

| Business Name | Address | Phone Number | Website |

|---|---|---|---|

| [Business Name 1] | [Address 1] | [Phone Number 1] | [Website 1] |

| [Business Name 2] | [Address 2] | [Phone Number 2] | [Website 2] |

| [Business Name 3] | [Address 3] | [Phone Number 3] | [Website 3] |

| [Business Name 4] | [Address 4] | [Phone Number 4] | [Website 4] |

| [Business Name 5] | [Address 5] | [Phone Number 5] | [Website 5] |

Comparison of Services Offered by Three Las Vegas Trailer Hitch Installers

This section compares the services, pricing, and special offers of three hypothetical Las Vegas trailer hitch installers. Remember that actual pricing and offers are subject to change and should be confirmed directly with the businesses.Let’s consider three hypothetical businesses: “Hitch Masters,” “Tow Town,” and “Trailer Tech.”Hitch Masters offers a wide range of hitch types and installation services, including custom fabrication for specialized vehicles.

Their pricing is generally considered mid-range, with packages starting around $300 and increasing based on hitch type and vehicle. They frequently offer seasonal discounts on specific hitch models.Tow Town focuses on quicker turnaround times and provides a more limited selection of pre-fabricated hitches. Their pricing is generally lower, starting around $250, but may lack the customization options offered by Hitch Masters.

They often run promotions on weekends.Trailer Tech provides a premium service with a comprehensive inspection and consultation before installation. They offer a wider selection of high-end hitches and their pricing reflects this, starting around $400. They occasionally offer loyalty programs for repeat customers.

Customer Review Processes of Three Las Vegas Trailer Hitch Installation Companies

Understanding the customer review process for each installer helps assess their commitment to customer satisfaction.Hitch Masters uses a combination of online reviews through platforms like Yelp and Google, as well as in-house customer satisfaction surveys. They actively respond to both positive and negative feedback.Tow Town primarily relies on online reviews on Google and their own Facebook page. They encourage customers to leave reviews and occasionally offer incentives for doing so.Trailer Tech utilizes a formal customer feedback system, including follow-up calls and emails to gather feedback on the installation process and overall customer experience.

They use this information to improve their services.

Types of Trailer Hitches and Installation Methods: Trailer Hitch Installation Las Vegas

Choosing the right trailer hitch for your vehicle is crucial for safety and functionality. The type of hitch you need depends primarily on the weight of the trailer you intend to tow. Understanding the different classes and installation methods will help you make an informed decision, whether you opt for a professional installation or a DIY project.

Trailer Hitch Classes and Weight Capacities

The capacity of a trailer hitch is determined by its class, ranging from Class I to Class V. Each class has specific weight limits for tongue weight (the downward force on the hitch ball) and towing capacity (the total weight of the trailer). Exceeding these limits can lead to dangerous situations.

- Class I: Typically used for small trailers such as utility trailers or cargo carriers. Tongue weight capacity is usually around 200-500 lbs, and towing capacity is typically under 2,000 lbs.

- Class II: Suitable for slightly larger trailers, such as small boat trailers or larger cargo carriers. Tongue weight capacity ranges from 350-750 lbs, and towing capacity generally reaches up to 3,500 lbs.

- Class III: The most common class for SUVs and light trucks. They handle a wide range of trailers, including larger cargo carriers, small boats, and travel trailers. Tongue weight capacity is typically between 500-1,000 lbs, and towing capacity can reach up to 10,000 lbs.

- Class IV: Designed for heavier-duty towing, often used with larger travel trailers, horse trailers, or utility trailers carrying substantial loads. Tongue weight capacity usually exceeds 1,000 lbs, and towing capacity can exceed 10,000 lbs.

- Class V: The heaviest-duty class, used for exceptionally large and heavy trailers, such as large horse trailers or heavy-duty equipment trailers. Tongue weight capacity and towing capacity are significantly higher than Class IV, often exceeding 12,000 lbs and 16,000 lbs respectively.

Class III Trailer Hitch Installation on an SUV

Installing a Class III hitch on an SUV generally requires basic mechanical skills and the right tools. Improper installation can compromise safety and void warranties.

- Gather Necessary Tools: This typically includes a socket wrench set, a torque wrench, jack stands, a jack, safety glasses, work gloves, and potentially a drill with appropriate drill bits (depending on the hitch design).

- Prepare the Vehicle: Securely raise the rear of the SUV using a jack and support it with jack stands for safety. Consult your vehicle’s owner’s manual for proper jacking points.

- Locate Mounting Points: The hitch installation instructions will specify the exact location of the mounting points on the vehicle’s frame. These points are typically reinforced areas designed to handle the stress of towing.

- Install the Hitch: Align the hitch with the mounting points and secure it using the provided bolts and hardware. Ensure the hitch is properly seated and aligned before tightening the bolts.

- Tighten Bolts: Use a torque wrench to tighten the bolts to the manufacturer’s specified torque settings. This ensures the hitch is securely attached and prevents damage.

- Lower the Vehicle: Carefully lower the SUV using the jack. Double-check that the hitch is securely mounted and that there are no loose bolts or components.

- Test the Hitch: Before towing, conduct a visual inspection and ensure the hitch is firmly attached. A slight test pull might be beneficial to confirm its stability.

DIY vs. Professional Trailer Hitch Installation

The decision of whether to install a trailer hitch yourself or hire a professional depends on your mechanical skills, comfort level, and available tools.

- DIY Installation: Pros: Cost savings. Cons: Requires mechanical aptitude, proper tools, and potentially more time. Incorrect installation can lead to safety hazards and damage to the vehicle.

- Professional Installation: Pros: Ensures proper installation, often includes a warranty, and saves time and effort. Cons: Higher cost. However, this is generally a worthwhile investment considering the safety implications involved.

Cost Considerations and Factors Affecting Price

The cost of trailer hitch installation in Las Vegas, like anywhere else, varies depending on several key factors. Understanding these factors can help you budget effectively and avoid unexpected expenses. This section provides a breakdown of typical costs and the elements influencing them. Accurate pricing always requires contacting a specific installer for a quote based on your vehicle and chosen hitch.The total cost typically comprises labor charges, the price of the hitch itself, and any additional fees the installer might charge.

You also will receive the benefits of visiting osrs hcim hiscores today.

Labor costs are influenced by the complexity of the installation, while the hitch’s price varies greatly depending on its type, brand, and capacity. Additional fees could include things like disposal of old parts or specialized tools required for certain vehicles.

Typical Cost Breakdown

The following table provides estimated cost ranges for trailer hitch installation in Las Vegas. Remember that these are estimates and actual costs may vary. Always obtain a quote from a reputable installer before proceeding.

| Vehicle Type | Estimated Cost Range (USD) |

|---|---|

| Cars (Sedans, Hatchbacks) | $200 – $500 |

| SUVs & Crossovers | $250 – $600 |

| Trucks (Light-Duty) | $300 – $700 |

| Trucks (Heavy-Duty) | $400 – $1000+ |

Factors Influencing Installation Cost

Several factors significantly impact the final cost of trailer hitch installation. Understanding these helps in better preparation and budget allocation.Vehicle Type: The type of vehicle greatly influences the complexity of installation. Cars generally have simpler installations compared to trucks, which often require more extensive modifications and potentially more labor hours. SUVs and crossovers fall somewhere in between.Hitch Type: Different hitch types have varying costs.

Class I hitches are typically the least expensive, designed for smaller loads, while Class III and IV hitches, suited for heavier loads, command higher prices. The material (steel vs. aluminum), weight capacity, and brand also play a role.Installation Complexity: Some vehicles require more extensive modifications for hitch installation than others. Factors such as the vehicle’s frame design, exhaust system placement, and electrical wiring requirements can increase labor costs.

Vehicles with advanced safety systems or complex underbody components may also require more specialized tools and expertise, thus increasing the overall expense.Additional Fees: Installers might charge extra fees for specific services. These could include the disposal of old parts, the addition of wiring harnesses for trailer lights, or the use of specialized tools. Always inquire about any potential additional charges upfront to avoid surprises.

Safety Precautions and Legal Requirements

Trailer hitch installation, while seemingly straightforward, requires careful attention to safety and adherence to legal regulations to ensure both the installer’s and vehicle owner’s well-being and compliance with Nevada law. Neglecting these aspects can lead to accidents, vehicle damage, and legal penalties.Proper installation is crucial for safe towing. Failing to follow safety procedures can result in serious injury or even death.

Similarly, ignoring legal requirements can lead to fines and legal repercussions. This section details the essential safety measures and legal compliance aspects relevant to trailer hitch installation in Nevada.

Safety Precautions During Trailer Hitch Installation

Several crucial safety precautions must be observed during the installation process. These precautions protect both the installer and the vehicle from potential harm. Failure to follow these guidelines can lead to serious injury or damage.

- Always use appropriate safety gear, including safety glasses, gloves, and sturdy work boots. This protects against potential injury from sharp edges, heavy components, and other hazards.

- Ensure the vehicle is securely parked on a level surface with the parking brake engaged. This prevents accidental movement during the installation process.

- Use jack stands to support the vehicle properly when working underneath. Never rely solely on a jack, as it could fail, leading to serious injury.

- Follow the manufacturer’s instructions meticulously. Each hitch and vehicle will have specific installation requirements that must be followed precisely.

- Use the correct tools for the job. Improper tools can damage components or cause injury.

- Take breaks to avoid fatigue, which can increase the risk of accidents.

- If unsure about any aspect of the installation, consult a qualified professional.

Legal Requirements and Regulations in Nevada

Nevada, like other states, has regulations governing the installation and use of trailer hitches. These regulations aim to ensure road safety and prevent accidents caused by improperly installed hitches. Specific examples of regulations might include limitations on hitch weight capacity relative to the vehicle’s towing capacity, requirements for proper lighting and signaling on trailers, and mandated inspections in certain circumstances.

It is crucial to consult the Nevada Department of Motor Vehicles (DMV) website or relevant publications for the most up-to-date and precise information on these regulations. Failure to comply with these regulations can result in fines, vehicle impoundment, or even legal action.

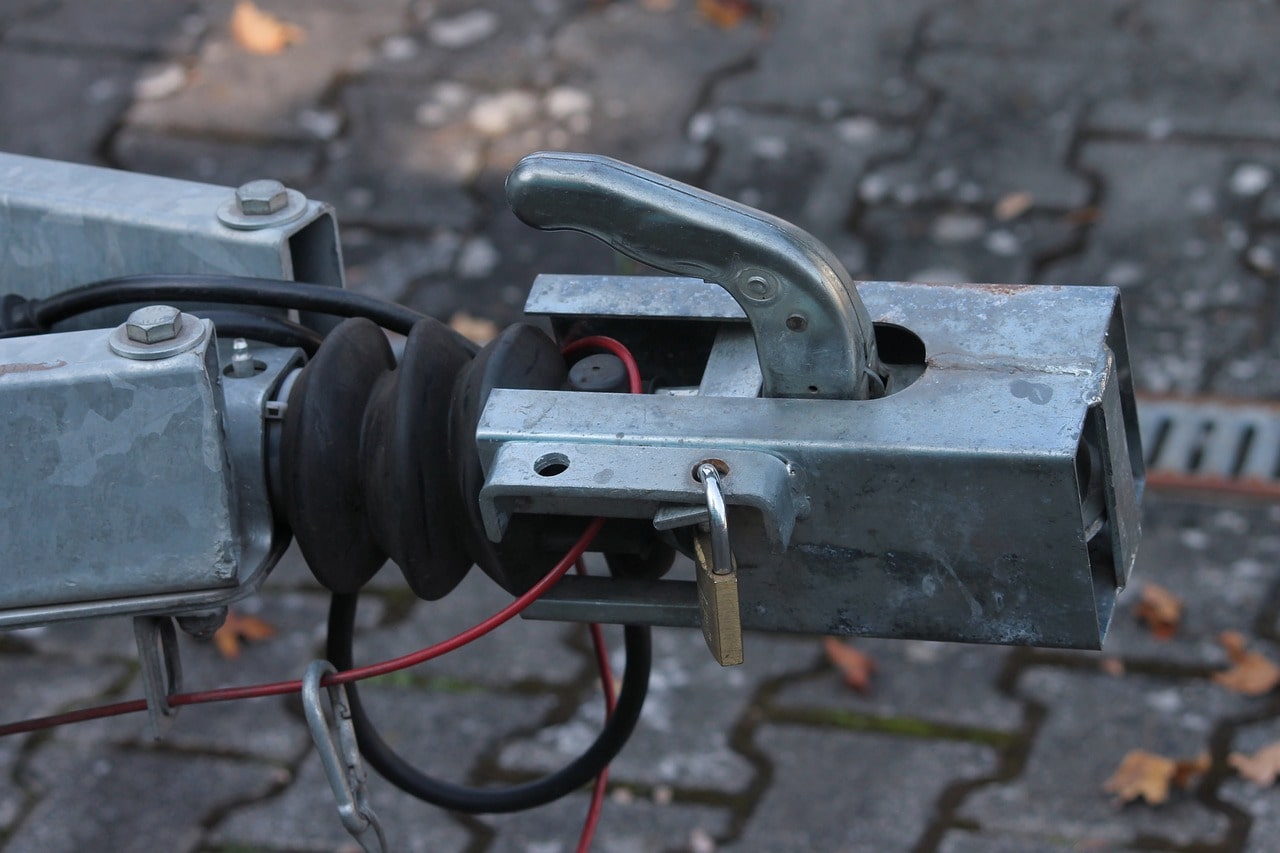

Visual Representation of a Properly Installed Trailer Hitch

Imagine a photograph of a vehicle with a trailer hitch installed. The hitch is securely bolted to the vehicle’s frame, with all bolts tightened to the manufacturer’s specified torque. The hitch receiver is clean, free of rust or damage, and positioned centrally. The safety chains are properly connected, with sufficient slack to allow for articulation but short enough to prevent excessive swing.

The wiring harness is neatly routed and securely connected to both the vehicle and the trailer’s lighting system. All safety components, including the hitch ball, are free of damage and securely fastened. In contrast, an improperly installed hitch might show loose bolts, misaligned components, damaged wiring, or inadequate safety chain connections. This could be visually evident as misaligned components, visible gaps between the hitch and vehicle frame, or exposed wiring.

These visual cues immediately highlight the potential hazards of improper installation, including the risk of hitch failure, electrical malfunctions, and compromised safety chain function, all of which can lead to serious accidents.

Maintaining and Caring for Your Trailer Hitch

Proper maintenance of your trailer hitch is crucial for ensuring its longevity, preventing accidents, and maintaining the safety of your vehicle and its cargo. Regular inspections and simple maintenance tasks can significantly extend the lifespan of your hitch and help avoid costly repairs or dangerous situations down the road. Neglecting maintenance can lead to premature wear, compromised safety, and even potential legal issues.Regular maintenance involves a series of straightforward checks and cleaning procedures.

These tasks are easily integrated into your vehicle’s overall maintenance schedule and require minimal time and effort. By consistently following these practices, you’ll ensure your hitch remains in optimal working condition.

Regular Maintenance Checklist, Trailer hitch installation las vegas

A comprehensive maintenance schedule will help prevent unforeseen problems. This checklist Artikels key inspection points and maintenance tasks to be performed at regular intervals.

- Visual Inspection (Monthly): Check for any signs of damage, such as cracks, bends, rust, or excessive wear on the hitch ball, receiver tube, and mounting hardware. Pay close attention to welds and the hitch’s connection points to the vehicle’s frame.

- Lubrication (Every 3 Months or 3,000 miles): Apply a high-quality lubricant, such as grease specifically designed for trailer hitches, to all moving parts, including the hitch ball, receiver tube, and pin. This reduces friction and wear, prolonging the hitch’s life.

- Tightness Check (Every 3 Months or 3,000 miles): Verify that all bolts and nuts connecting the hitch to the vehicle are securely tightened. Use a torque wrench to ensure they are tightened to the manufacturer’s specifications. Loose connections can lead to serious safety hazards.

- Corrosion Prevention (Annually): Clean the hitch thoroughly with a wire brush or other suitable tool to remove dirt, debris, and rust. Apply a rust-preventative coating, such as paint or a specialized rust inhibitor, to protect against corrosion, especially in areas prone to moisture.

Common Trailer Hitch Problems and Troubleshooting

Several common issues can arise with trailer hitches. Addressing these problems promptly can prevent further damage and ensure continued safe operation.

- Loose Hitch: If the hitch feels loose or wobbly, immediately stop using it and check all bolts and connections. Tighten any loose components or replace damaged hardware. A loose hitch can cause instability and potentially lead to an accident.

- Bent or Damaged Hitch: A bent or damaged hitch should be repaired or replaced immediately. Do not attempt to use a damaged hitch, as it may fail under load, causing significant damage and posing a safety risk. Consult a professional for repair or replacement.

- Rust and Corrosion: Regular cleaning and application of a rust preventative will minimize corrosion. Severe corrosion can weaken the hitch structure, compromising its integrity. If significant corrosion is present, consider replacing the hitch.

Connecting and Disconnecting a Trailer

Safe connection and disconnection procedures are essential to prevent accidents and damage. Follow these steps meticulously.

- Parking: Park your vehicle on a level surface with the parking brake engaged.

- Hitch Alignment: Align the trailer hitch ball with the receiver tube on the vehicle’s hitch.

- Connection: Gently guide the trailer hitch ball into the receiver tube. Ensure it’s fully seated and secure.

- Securing the Hitch: Insert the hitch pin and clip or locking mechanism, ensuring it is properly engaged. Double-check that the pin is securely fastened.

- Safety Chains: Connect the safety chains in a crisscross pattern, ensuring they are not too tight or too loose.

- Lights and Wiring: Connect the trailer lights to the vehicle’s wiring harness, ensuring all lights are functioning correctly.

- Disconnection: Reverse the process for disconnection, ensuring the pin and clip are removed safely before separating the trailer.

Successfully installing a trailer hitch in Las Vegas involves careful planning and execution. By understanding the different hitch types, considering the costs involved, prioritizing safety, and performing regular maintenance, you can ensure a secure and reliable towing experience for years to come. Remember to always prioritize safety and consult with professionals when needed. Happy towing!